Moisture and 3D Printing – Part 1 – An Introduction to Absorption

In FDM printing, the moisture present in the filament plays a big role in whether a part is printed successfully or not. In this series of articles we will explain the interaction between moisture and 3D printing, as well as how to counteract and prevent moisture absorption.

The first article will be discussing how plastics react to moisture, and what effects this has on their properties.

What is moisture?

The word moisture describes the presence of slight-to-moderate amount of liquid, most commonly water, as a vapor, within a solid or condensed on a surface. When it comes to defining the moisture in the air, we talk about humidity. The moisture or humidity of an environment describes the amount of water vapor in the environment’s air. Depending on the situation, moisture could either be detrimental or beneficial. For instance, it is good to have a humid environment in a greenhouse, but humidity could be dangerous in old houses with mould issues.

Different polymers and moisture

There are various polymers that are used for 3D printing, and they all react to moisture differently. Some are very hygroscopic, and will readily absorb moisture from the air, while some are less hygroscopic and will not absorb as much moisture. This section will briefly discuss some polymers and their affinity to moisture.

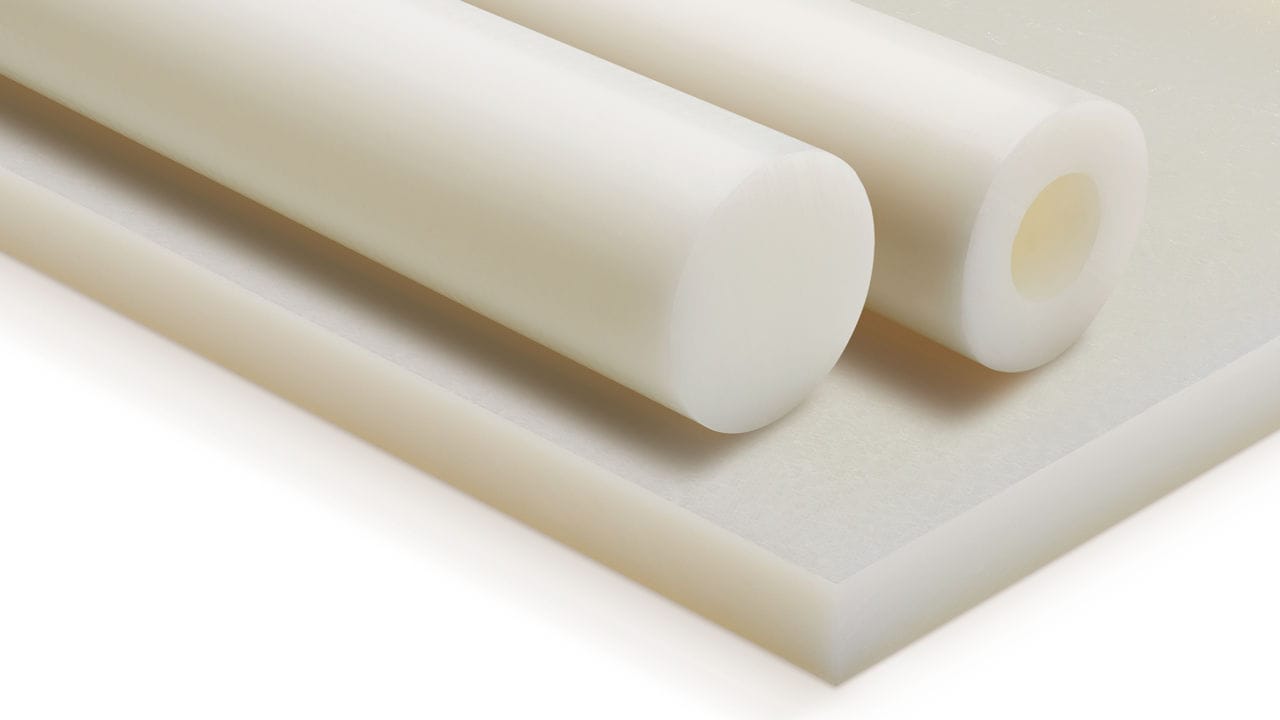

Nylon/Polyamide

Nylon materials are among the most used engineering thermoplastics in the 3D printing industry due to their high versatility. Nylons typically have high strength, good chemical resistance and good fatigue resistance.

All nylons are hygroscopic, and this property plays an important role during 3D Printing. The rate of moisture absorption in nylons depends heavily on the the ambient temperature and relative humidity. As a general rule, materials tend to absorb more moisture when the environmental humidity is higher. The level of moisture in nylons will have an impact on the material’s properties. The absorbed water molecules act as a plasticizer in nylons. This means that it will alter some mechanical properties, such as yield strength, tensile modulus and glass transition temperature.

For more information about Nylons and how to print them, check out this blog post all about Nylons.

Acrylonitrile butadiene styrene (ABS)

ABS is a commonly used thermoplastic which is used in various industries. As a material, ABS has high durability, which plays an important part in the design of parts made from this material. Unlike Nylons, ABS does not absorb moisture as readily, and absorption is very slow at room temperature. That being said, the rate of absorption is still dependent on the humidity and temperature of the environment.

As the absorbed moisture in ABS increases, the tensile properties of the material decrease linearly. The extent of this decrease, as well as which properties actually decrease depends a lot on the fabrication process. ABS parts created through injection molding will have different properties than an ABS part created through 3D printing.

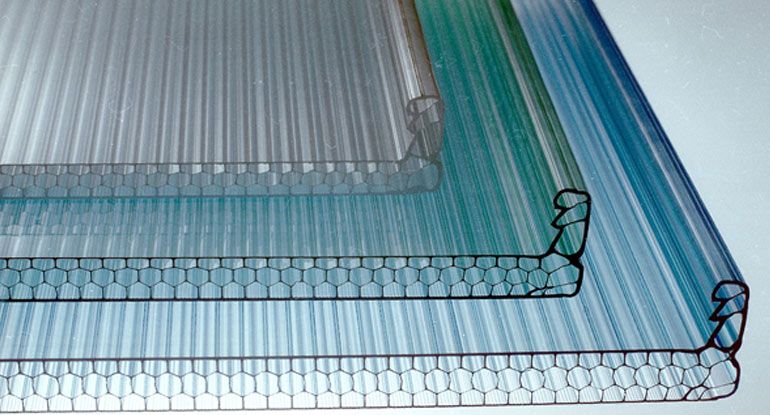

Polycarbonate (PC)

Polycarbonates are engineering thermoplastics that are transparent by nature and amorphous. They are used extensively in engineering industries due to their versatility when it comes to mechanical properties and recyclability.

Although polycarbonates are not as hygroscopic as nylons, moisture absorption still severely affects the way that they are processed, especially when exposed to high humidity and temperature. Exposure to prolonged humidity also puts the material through a ductile-to-brittle transition. Moreover, moisture absorption lowers the tensile properties of polycarbonates, allowing for more crack growth and propagation to the fracture surface. This presents itself as a decrease in tensile strength of the material itself.

For more information about PC and how to print it, check out one of our earlier blog posts all about PC.

Moisture and 3D Printing

We have seen that polymers that have absorbed moisture have some of their properties deteriorate. When it comes to 3D printing, this deterioration of properties has a negative reaction on the final product. Each material has its own issues when it comes to 3D printing, and in the upcoming blogs in this series we will be delving into these issues. We will be discussing moisture and 3D printing, as well as how to counteract and remove moisture from filaments. Stay tuned!